Cutting Tools Market Share Key Players Leading the Global Market

The Cutting Tools Market Share is held by several key players who dominate through innovation and extensive distribution networks. Major manufacturers are focusing on expanding their product portfolios and enhancing their market presence through strategic partnerships and acquisitions. Competitive strategies include the development of advanced materials and coatings that improve tool performance and longevity. As the market evolves, companies that prioritize customization and technological advancements in cutting tools are likely to gain a larger share, reflecting the changing demands of various industries.

The cutting tools market is an essential component of the manufacturing and industrial sector, providing solutions for material removal, shaping, and machining. Cutting tools are utilized across a range of industries, including automotive, aerospace, construction, electronics, and metalworking. They include products such as drills, milling cutters, turning tools, threading tools, and reamers, manufactured from materials like high-speed steel (HSS), carbide, ceramics, and diamond. With the rise of advanced manufacturing technologies, including CNC machining and automated production lines, the demand for high-performance cutting tools has surged, making them critical for precision engineering and efficiency in production processes.

Market Drivers

The growth of the cutting tools market is driven by several factors. Increasing industrialization and manufacturing activities are creating higher demand for metal cutting, shaping, and machining solutions. Technological advancements in materials and coatings, such as carbide-tipped tools, diamond coatings, and ceramic composites, enhance tool durability, performance, and efficiency. Additionally, the adoption of CNC machines and automated machining centers has increased the need for precise and reliable cutting tools that can withstand high-speed operations. The automotive and aerospace sectors, in particular, drive demand for cutting tools due to their need for complex, high-precision components.

Market Segmentation

The cutting tools market can be segmented by type, material, application, and end-user industry. Tool types include turning tools, milling tools, drills, reamers, and threading tools, each serving specific machining requirements. By material, cutting tools are made from high-speed steel, carbide, ceramic, cubic boron nitride (CBN), and polycrystalline diamond (PCD), offering different advantages in terms of strength, wear resistance, and cost. Applications range from general machining and metalworking to precision industries such as aerospace and electronics. End-users span automotive, aerospace, metal fabrication, energy, and industrial machinery sectors.

Technological Advancements

Innovation is a critical driver in the cutting tools market. Advanced coatings such as titanium nitride (TiN), aluminum titanium nitride (AlTiN), and diamond-like carbon (DLC) enhance wear resistance and prolong tool life. High-performance materials like carbide, ceramic, and CBN allow cutting of hard metals and alloys with minimal wear. CNC machines integrated with smart cutting tools provide real-time monitoring and predictive maintenance, optimizing machining processes and reducing downtime. Additive manufacturing and hybrid machining processes are also shaping the market by enabling new cutting tool designs and improving overall efficiency.

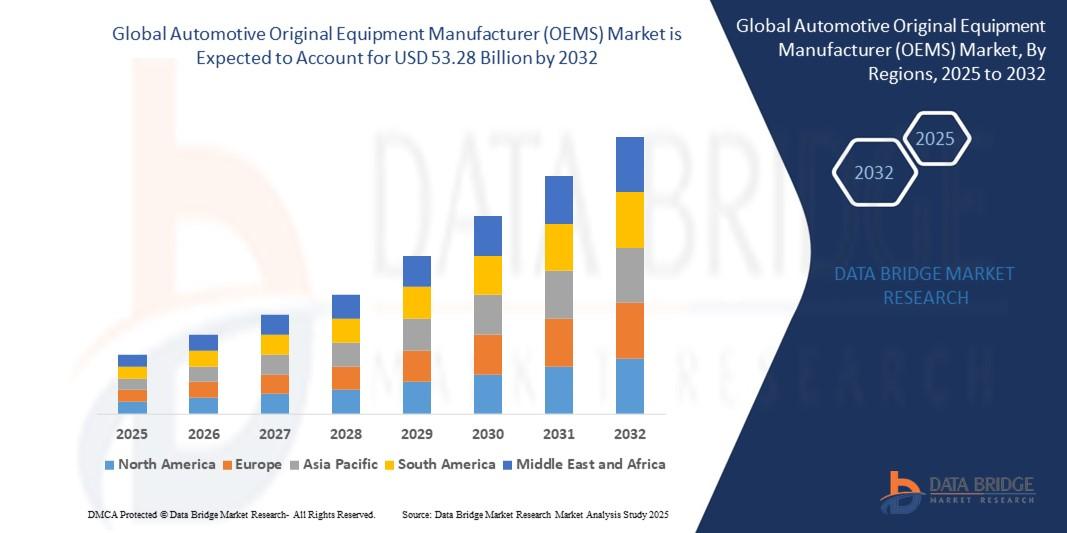

Regional Insights

The cutting tools market is geographically diverse. North America and Europe hold mature markets due to the presence of established manufacturing industries and advanced technological adoption. Asia-Pacific, led by China, Japan, and India, is the fastest-growing market, fueled by industrial expansion, automotive production, and metalworking activities. Emerging economies in Asia and Latin America offer significant growth opportunities due to increasing manufacturing investments, infrastructure development, and the rising adoption of modern machining technologies.

Challenges and Opportunities

Despite its growth, the cutting tools market faces challenges such as high production costs for advanced tools and competition from low-cost alternatives. Tool wear, downtime, and the need for skilled operators are additional operational challenges. However, opportunities abound in the development of high-performance, long-life tools, and solutions for smart manufacturing. The push towards sustainable manufacturing, precision machining, and automation is opening new avenues for market players to provide innovative, high-value tools.

Future Outlook

The future of the cutting tools market looks robust, with steady growth driven by technological innovation, automation, and industrial expansion. The demand for durable, high-performance, and smart cutting tools is expected to rise across all major manufacturing sectors. Companies investing in research and development, tool coating technologies, and CNC integration will be well-positioned to capture market share. The ongoing trend toward Industry 4.0 and smart manufacturing will further enhance the demand for precision cutting tools, ensuring the market remains competitive and dynamic.

FAQs

1. What industries primarily use cutting tools?

Automotive, aerospace, metalworking, electronics, and industrial machinery sectors are the main users.

2. What materials are used in cutting tools?

High-speed steel, carbide, ceramics, cubic boron nitride (CBN), and polycrystalline diamond (PCD) are commonly used materials.

3. Are there technological innovations in cutting tools?

Yes, advancements include coated tools, smart CNC integration, wear-resistant materials, and hybrid machining processes.