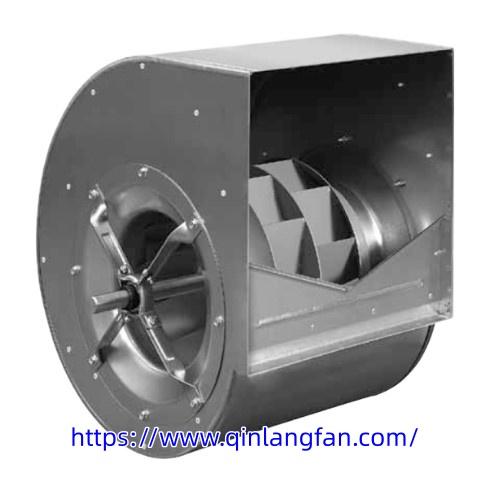

How Does Qinlang Multi Stage Centrifugal Fan Supplier Handle Spikes?

Stable operation in ventilation systems depends on precise understanding of pressure fluctuations. Qinlang's Multi Stage Centrifugal Fan Supplier provides advanced multi-stage fans designed to withstand variable pressures while delivering consistent airflow. Careful analysis of steady-state and transient pressures guides structural design, ensuring walls, supports, and impellers endure operational stresses without deformation or fatigue.

Sudden spikes or backflow events can challenge fan integrity. By modeling dynamic pressure responses, engineers identify vulnerable regions and optimize casing geometry, reinforcing areas prone to stress concentration. Numerical simulations allow testing of extreme scenarios, enabling design adjustments that reduce material strain and maintain airflow continuity even under fluctuating conditions.

Flow-induced vibrations impact fan reliability and component longevity. Understanding structural response mechanisms helps engineers select materials with high fatigue resistance and incorporate damping solutions at key junctions. This approach prevents resonance, protects bearings and shafts, and maintains consistent stage-to-stage performance without compromising energy efficiency.

Design must also account for cumulative stress over long operational periods. Repetitive pressure variations can induce micro-deformations, which over time may compromise alignment and airflow distribution. Using predictive models, designers anticipate these effects, reinforcing critical areas and ensuring that system stability remains intact throughout the fan lifecycle.

Aerodynamic optimization complements structural resilience. Smooth impeller profiles, precise tip clearances, and controlled blade angles reduce turbulence and limit pressure pulsations. These refinements allow the fan to operate efficiently while reducing mechanical stress, preserving component integrity, and maintaining quiet and stable operation across the network.

Integration of monitoring systems supports continuous assessment of pressure and vibration. Sensors capture data on fluctuations, enabling operators to intervene proactively. Adjustments in stage speed, vane orientation, or load balancing can be made in real time, preventing damage, extending service life, and ensuring safe, uninterrupted airflow throughout multi-branch duct networks.

Energy distribution is enhanced by coordinating multiple stages. Gradual pressure increases through each fan stage prevent overloading and reduce wear on critical components. Stage alignment, aerodynamic control, and precise mechanical support work together, converting input energy effectively into reliable airflow while minimizing internal stresses.

Ultimately, facilities requiring precision airflow and structural reliability benefit from multi-stage fans engineered with advanced pressure analysis and robust structural mechanisms. Qinlang and Multi Stage Centrifugal Fan Supplier offer solutions combining adaptive monitoring, material resilience, and optimized stage design, ensuring continuous, efficient, and safe operation. For more information, visit https://www.qinlangfan.com/