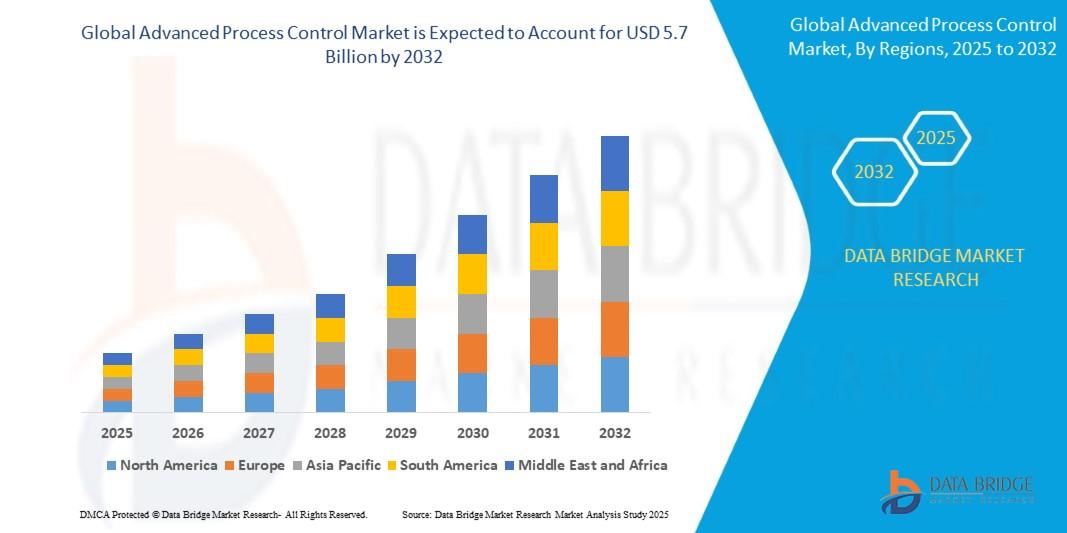

Advanced Process Control Market Demand: Growth, Share, Value, Size, and Insights

1. Executive Summary

The Global Advanced Process Control (APC) Market is undergoing rapid expansion as industries across the world increasingly embrace automation, digital transformation, and real-time process optimization. APC technologies—ranging from Model Predictive Control (MPC) to inferential and multivariable control solutions—have become fundamental components in industries that rely on high-precision, high-throughput, and energy-efficient operations.

Growing demand for improved operational efficiency, enhanced production yields, reduced downtime, and minimized resource wastage has accelerated APC adoption across sectors such as oil & gas, chemicals, power generation, pharmaceuticals, mining, and food & beverage. As industrial facilities modernize under Industry 4.0 and move toward AI-driven systems, APC is becoming a centerpiece of advanced manufacturing.

The market’s trajectory is shaped by increasing complexity in industrial processes, rising competition, and heightened regulatory pressures regarding safety, sustainability, and environmental compliance. Companies are also adopting APC in conjunction with cloud platforms, digital twins, industrial IoT (IIoT), and predictive analytics—all of which are transforming process automation into a highly intelligent and adaptive ecosystem.

Review comprehensive data and projections in our Global Advanced Process Control Market report.

Download now: https://www.databridgemarketresearch.com/reports/global-advanced-process-control-market

2. Market Overview & Dynamics

Understanding Advanced Process Control (APC)

APC is a set of software-based tools and advanced algorithms designed to optimize, control, and improve industrial processes. While conventional control systems operate based on basic parameters, APC enhances them by applying multivariable models, prediction techniques, and real-time data analytics.

APC systems help industries:

Improve product quality

Minimize material loss

Reduce energy consumption

Enhance operational consistency

Manage complex process variables

Key Market Drivers

1. Rising Adoption of Industry 4.0

Smart factories require intelligent automation tools that can interpret and optimize real-time operational data. APC aligns perfectly with this requirement.

2. Need for Operational Efficiency

Industries face increasing pressure to reduce downtime, minimize energy costs, and improve throughput. APC provides quantitative improvements, often significantly impacting profitability.

3. Growth in Complex Industrial Processes

As industrial environments become more advanced, traditional control systems fall short. APC offers a solution for sophisticated processes with interdependent variables.

4. Regulatory and Environmental Compliance

Process industries are compelled to adopt technologies that support emissions reduction and safer operations. APC helps maintain optimal conditions within regulatory limits.

Market Restraints

High initial investment in software, integration, and specialized training

Slow modernization in certain regions

Complexity in system deployment and maintenance

Existing legacy systems that are not APC-compatible

Opportunities

Integration with AI, ML, and cloud for smarter optimization

Expansion in Asia-Pacific’s fast-growing industrial sector

Increasing adoption of digital twins for simulation-based process optimization

Growing awareness of APC’s ROI benefits in industries previously slow to change

3. Market Trends & Innovations

1. AI-Enhanced APC Systems

Companies are developing APC systems that incorporate machine learning algorithms capable of self-optimization and adaptive control. AI enhances predictive accuracy and reduces operator intervention.

2. Cloud-Based APC Deployment

Cloud platforms enable large-scale data processing, remote access, and centralized monitoring, making APC systems more scalable and cost-effective.

3. Digital Twins & Simulation-Driven Control

Manufacturers are increasingly pairing APC solutions with digital twins to predict equipment behavior, improve maintenance planning, and simulate process improvements.

4. Real-Time Optimization (RTO)

RTO tools work alongside APC systems to adjust process variables dynamically, ensuring the best economic and operational output in real time.

5. Integration with IoT Sensors & Edge Devices

The proliferation of industrial IoT sensors has enhanced data availability, enabling APC solutions to function with greater precision and responsiveness.

6. Energy Optimization Applications

APC systems are now widely used to reduce energy consumption in industries such as petrochemicals, refining, and metals processing, supporting sustainability initiatives.

4. Market Segmentation Analysis

By Technology

Model Predictive Control (MPC): Dominates due to its ability to predict future outcomes and manage multivariable constraints.

Advanced Regulatory Control (ARC): Enhances baseline regulatory loops for improved stability.

Inferential Control: Estimates key variables when real-time measurements are costly or impractical.

Multivariable Control: Addresses complex environments with multiple interacting process variables.

By Component

Software: The largest segment, driven by upgrades and new installations.

Services: Includes consulting, integration, training, and maintenance—critical due to system complexity.

Hardware: Involves controllers, sensors, and integration units supporting APC systems.

By Deployment Mode

On-Premise: Preferred by large enterprises with stringent process and data control requirements.

Cloud-Based: Growing rapidly due to scalability, lower cost, and easier updates.

By End-User Industry

Oil & Gas

One of the largest users of APC, especially in refining, petrochemicals, and LNG facilities.

Chemicals & Petrochemicals

APC enhances product uniformity, yield, and energy efficiency.

Pharmaceuticals

Ensures batch consistency, compliance, and quality control.

Power Generation

Used to optimize load distribution, reduce emissions, and ensure grid stability.

Mining & Metals

Improves extraction processes, flotation efficiency, and equipment utilization.

Food & Beverage

Provides consistency in production, reduces waste, and supports quality standards.

5. Regional Insights

North America

A mature APC market driven by strong automation adoption, advanced manufacturing environments, and high R&D investments. Oil & gas and chemicals are major contributors.

Europe

Europe emphasizes energy efficiency and sustainability, driving APC adoption across manufacturing and process industries. Germany, France, the UK, and Italy lead the region.

Asia-Pacific

The fastest-growing region due to industrial expansion in China, India, Japan, and South Korea. Increasing adoption of digitalization and manufacturing modernization drives demand.

Latin America

Growth is driven by oil & gas operations, mining industries, and modernization of manufacturing setups.

Middle East & Africa

APC demand is rising rapidly due to the petrochemical and refining sectors, particularly in Gulf countries focused on energy optimization and operational safety.

6. Competitive Landscape

The APC market includes established automation giants as well as specialized vendors offering domain-specific solutions. Competition is characterized by technological innovation, strategic collaborations, service enhancements, and the integration of AI and cloud capabilities.

Key competitive strategies include:

Launching next-generation predictive control systems

Expanding service portfolios and technical consulting offerings

Collaborating with cloud providers and IoT platforms

Integrating APC with broader automation and control suites

Investing in simulation, digital twins, and AI-based optimization technologies

Vendors are increasingly differentiating through customization, high interoperability, and real-time advanced analytics capabilities.

7. Future Market Outlook & Opportunities

The future of the Advanced Process Control market is closely tied to the evolving landscape of intelligent manufacturing. As industries continue to prioritize data-driven operations, the demand for smarter, self-learning process control systems will increase.

Key Future Opportunities:

1. Fusion of APC with AI & Machine Learning

Self-optimizing APC systems capable of autonomous corrections will become standard in next-generation manufacturing facilities.

2. Growth of Digital Twins

Real-time simulation and modeling will allow companies to forecast outcomes more accurately and improve decision-making.

3. APC-as-a-Service (APCaaS)

The shift toward cloud-based subscription models will make APC more affordable for mid-sized enterprises.

4. Energy Efficiency & Sustainability

Global sustainability goals will push industries to adopt APC to reduce resource consumption and carbon emissions.

5. Expansion in Emerging Markets

Industrial growth in Asia-Pacific, Africa, and Latin America will create significant new revenue opportunities for APC vendors.

In summary, the APC market is set for substantial long-term growth as industries embrace digital transformation, AI-driven optimization, and automation frameworks.

8. Conclusion

The Global Advanced Process Control (APC) Market is evolving into a critical enabler of smart, efficient, and future-proof industrial operations. As industries confront increasing complexity, market pressure, and sustainability requirements, APC systems provide a powerful pathway to improved performance, reduced costs, and enhanced competitiveness.

With continuous innovations in machine learning, IIoT integration, real-time optimization, digital twins, and cloud platforms, APC is not only a tool for process control but a foundation for the future of intelligent manufacturing.

📌 Frequently Asked Questions (FAQ)

1. What is Advanced Process Control (APC)?

APC is a set of advanced automation technologies that use predictive models, analytics, and real-time optimization to manage complex industrial processes more effectively than traditional control systems.

2. Which industries benefit the most from APC?

Oil & gas, chemicals, pharmaceuticals, power generation, mining, and food & beverage are among the leading adopters due to their high complexity and performance-driven operations.

3. Why is APC important for Industry 4.0?

APC enables smart automation, real-time data-driven optimization, and predictive adjustments—all essential components of intelligent manufacturing systems.

4. What role does AI play in APC?

AI enhances APC by improving prediction accuracy, enabling self-learning capabilities, and reducing operational intervention.

5. Is cloud-based APC gaining popularity?

Yes, cloud-based APC offers scalability, cost efficiency, remote access, and easier integration with digital platforms, making it increasingly attractive.

6. What challenges are associated with APC implementation?

Major challenges include high installation costs, integration complexity, workforce training needs, and compatibility with legacy systems.

7. What trends will shape the future of the APC market?

AI-driven optimization, digital twin adoption, APC-as-a-Service models, and sustainability-focused applications will drive the next decade of growth.

Browse More Reports:

North America Alkylation Market

Global Wastewater Treatment Chemicals Market

Global Smart Agriculture Market

Global Optical Instrument and Lens Market

Global Audio Streaming OTT Platform Market

Global Ruminant Methane Reduction Market

Global A2 Milk Market

Global Industrial IoT Market

Global Ultra-Secure Smartphone Market

Global Dairy Starter Culture Market

Global Direct Marketing Market

Global Relational Database Market

Global Benzodiazepine Drugs Market

Global Building Asphalt Market

Global Cloud Database Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- corporatesales@databridgemarketresearch.com