Vacuum Pumps Market size, trends, and emerging opportunities in industrial applications

As Per Market Research Future, the Vacuum Pumps Market is witnessing significant growth due to increasing demand across various industries, including pharmaceuticals, food processing, and electronics. The need for efficient vacuum solutions to enhance production processes and maintain product quality is driving market expansion. Additionally, technological advancements in vacuum pump designs and materials are contributing to improved performance and energy efficiency. As industries continue to prioritize automation and quality control, the vacuum pumps market is expected to experience robust growth in the coming years.

The vacuum pumps market has witnessed significant growth as industries continue to require efficient solutions for air and gas removal in various processes. Vacuum pumps are vital in sectors such as pharmaceuticals, chemical processing, semiconductors, food packaging, and laboratories. These pumps ensure controlled environments, prevent contamination, and support energy-efficient operations, making them indispensable in modern industrial applications.

Types of Vacuum Pumps

Vacuum pumps are categorized into positive displacement and momentum transfer types. Positive displacement pumps, such as rotary vane and diaphragm pumps, are commonly used for applications requiring low to medium vacuum levels. Momentum transfer pumps, including diffusion and turbo-molecular pumps, are suited for high vacuum applications, such as semiconductor manufacturing and research laboratories. Continuous innovation has resulted in hybrid vacuum pumps that combine multiple technologies for optimized performance.

Market Growth Drivers

The global vacuum pumps market is propelled by the rising demand for advanced manufacturing processes and laboratory applications. Increasing industrial automation, stringent quality control standards, and the expansion of semiconductor and electronics industries are driving the need for reliable vacuum solutions. Additionally, energy-efficient and low-maintenance vacuum pumps are gaining popularity due to cost-saving benefits and regulatory compliance.

Technological Advancements

Recent technological developments have significantly enhanced the efficiency and reliability of vacuum pumps. Advanced materials reduce wear and tear, prolonging equipment lifespan. Smart vacuum pumps equipped with sensors enable real-time monitoring and predictive maintenance, minimizing downtime. Furthermore, low-noise, oil-free pumps are gaining traction in cleanroom and pharmaceutical environments, addressing both environmental and health concerns.

Regional Market Analysis

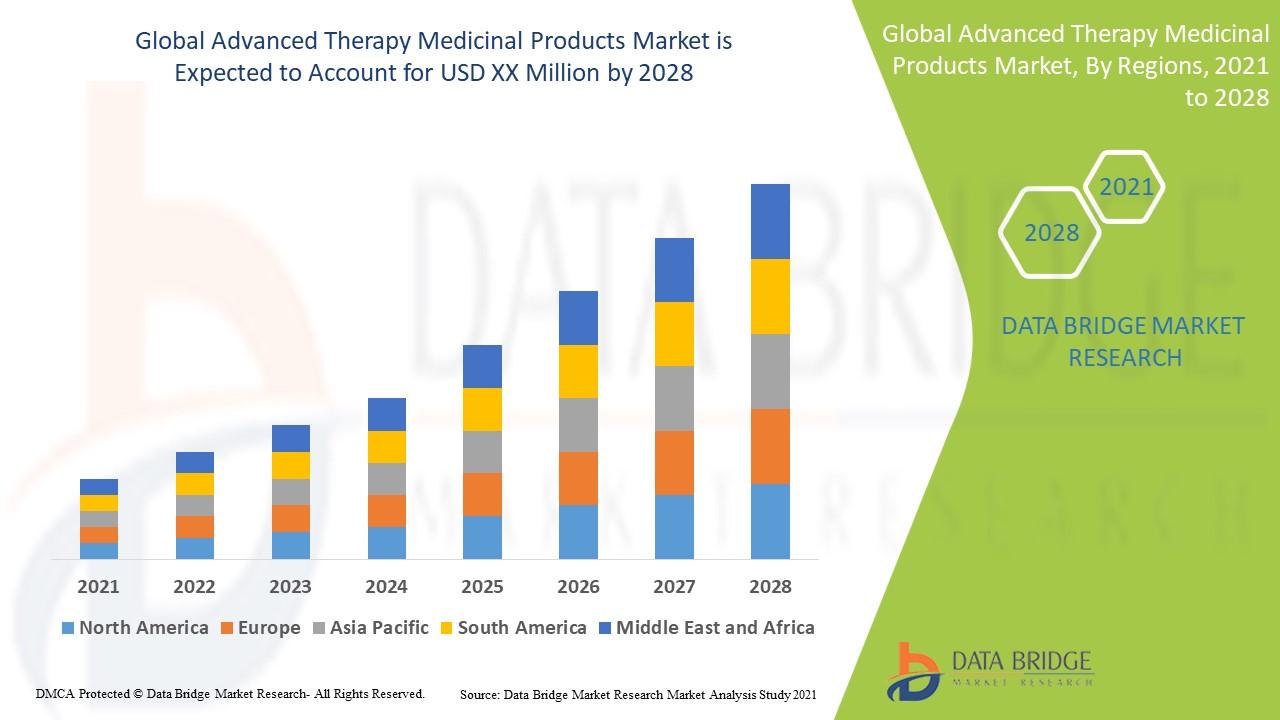

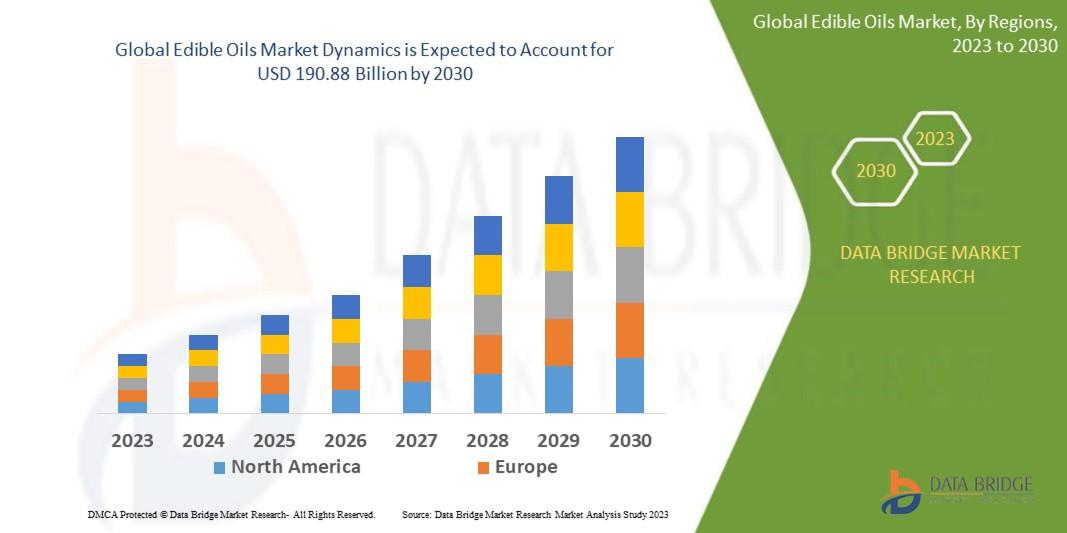

Regionally, North America and Europe dominate the vacuum pumps market, driven by technological adoption and established industrial infrastructure. Asia-Pacific is experiencing rapid growth due to increasing electronics manufacturing, pharmaceutical production, and chemical processing activities. Emerging economies in Latin America and the Middle East are also witnessing rising demand for industrial and laboratory vacuum solutions, offering significant growth opportunities for manufacturers.

Market Challenges

The vacuum pumps market faces certain challenges, including high maintenance requirements for specific pump types and the complexity of integrating advanced systems into existing industrial setups. Additionally, fluctuating raw material costs and energy consumption concerns may impact pricing and adoption rates. Manufacturers must invest in continuous innovation and training to ensure optimal performance and compliance with evolving industry standards.

Future Prospects

The future of the vacuum pumps market looks promising, with growth driven by industrial expansion, technological advancements, and sustainability initiatives. Integration of IoT-enabled monitoring systems, energy-efficient designs, and oil-free pumps is expected to enhance market competitiveness. As industries continue to focus on process optimization and environmental compliance, vacuum pumps will remain a crucial component across multiple sectors.

FAQs

Q1. What are the main applications of vacuum pumps?

Vacuum pumps are used in pharmaceuticals, electronics manufacturing, chemical processing, food packaging, and research laboratories.

Q2. What is the difference between oil-free and oil-lubricated vacuum pumps?

Oil-free pumps reduce contamination risk and are ideal for clean environments, whereas oil-lubricated pumps generally offer higher efficiency and durability in heavy-duty applications.

Q3. How are smart vacuum pumps improving industrial processes?

Smart vacuum pumps provide real-time monitoring, predictive maintenance, and energy optimization, enhancing efficiency and reducing operational costs.

More Related Reports:

Personal Protective Equipment Market Growth