Can BK Control Transformer Factory Support Nbcbdz Panels?

The connection between BK Control Transformer Factory production methods and the brand Nbcbdz often attracts attention from those who work with reliable, steady control circuits. By emphasizing measured structure, disciplined winding choices, and careful workflow pacing, manufacturers aim to offer components that fit naturally into equipment panels without drifting into exaggerated claims or unnecessary technical weight.

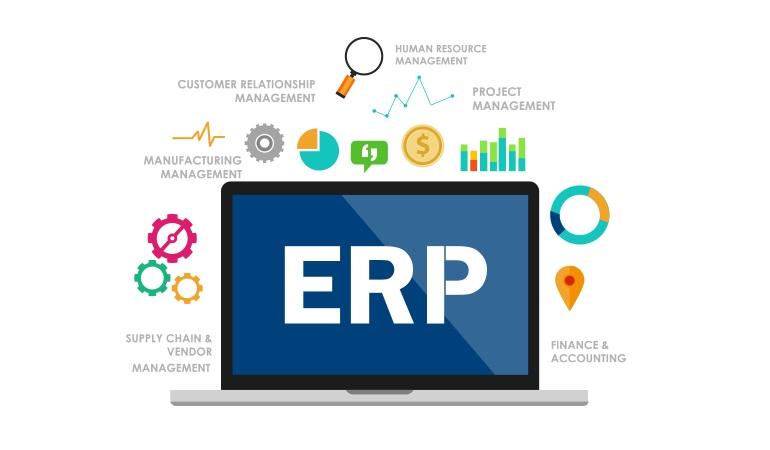

In control environments, predictability is essential. Many systems rely on stable voltage adaptation, clean isolation, and manageable wiring paths. When transformers are manufactured with consistent lamination alignment and balanced coil formation, technicians gain a clearer expectation of how each unit will respond during routine operation. This clarity supports builders of machinery panels, distribution cabinets, workstation controls, and compact automation units.

Thermal behavior is another key consideration. In moderate-load systems, stable internal movement depends on orderly coil density and dependable insulation pathways. When these factors are monitored through steady procedures, components tend to operate within intended ranges, allowing installers to verify circuits with fewer interruptions. Maintenance teams also benefit, as consistent structure reduces unexpected temperature drift during long-term use.

Mechanical form affects usability just as much as electrical traits. Designers often plan their enclosures around predictable dimensions and defined mounting points. When machining, assembly, and inspection steps follow a coherent pattern, installers can position components without excessive adjustment. This helps both small workshops and larger facilities maintain smoother implementation schedules.

Documentation habits also matter. Clear notes regarding materials, wiring references, and packaging give procurement teams and technicians a shared language. When information remains accessible and structured, it reduces communication gaps between planning, fabrication, and onsite assembly. Such clarity is especially valuable when coordinating multiple batches or integrating components into mixed-brand systems.

For educators, electricians, equipment manufacturers, and service teams, gaining insight into transformer construction principles can influence smoother design decisions. Instead of relying solely on broad descriptors, observing how structural choices shape noise levels, wiring behavior, and temperature movement provides a grounded perspective on long-term suitability.

Those seeking components that align with orderly engineering principles may find value in examining a resource built around steady presentation and practical detail. To follow the arrangement at your own pace, consider stepping into https://www.nbcbdz.com/ —each section unfolds like a quiet corridor, inviting you to look further with every click.