Wire Rope Sling Market Growth – Opportunities Across Global Sectors

The wire rope sling market growth trajectory is promising, driven by the rising need for secure and efficient load-handling solutions. Construction booms in emerging economies, coupled with the expansion of ports and oil exploration activities, are key contributors to this growth. Innovations such as corrosion-resistant coatings and advanced fabrication techniques are further propelling adoption. Additionally, market growth is supported by strict workplace safety regulations that encourage industries to invest in high-quality, certified lifting products.

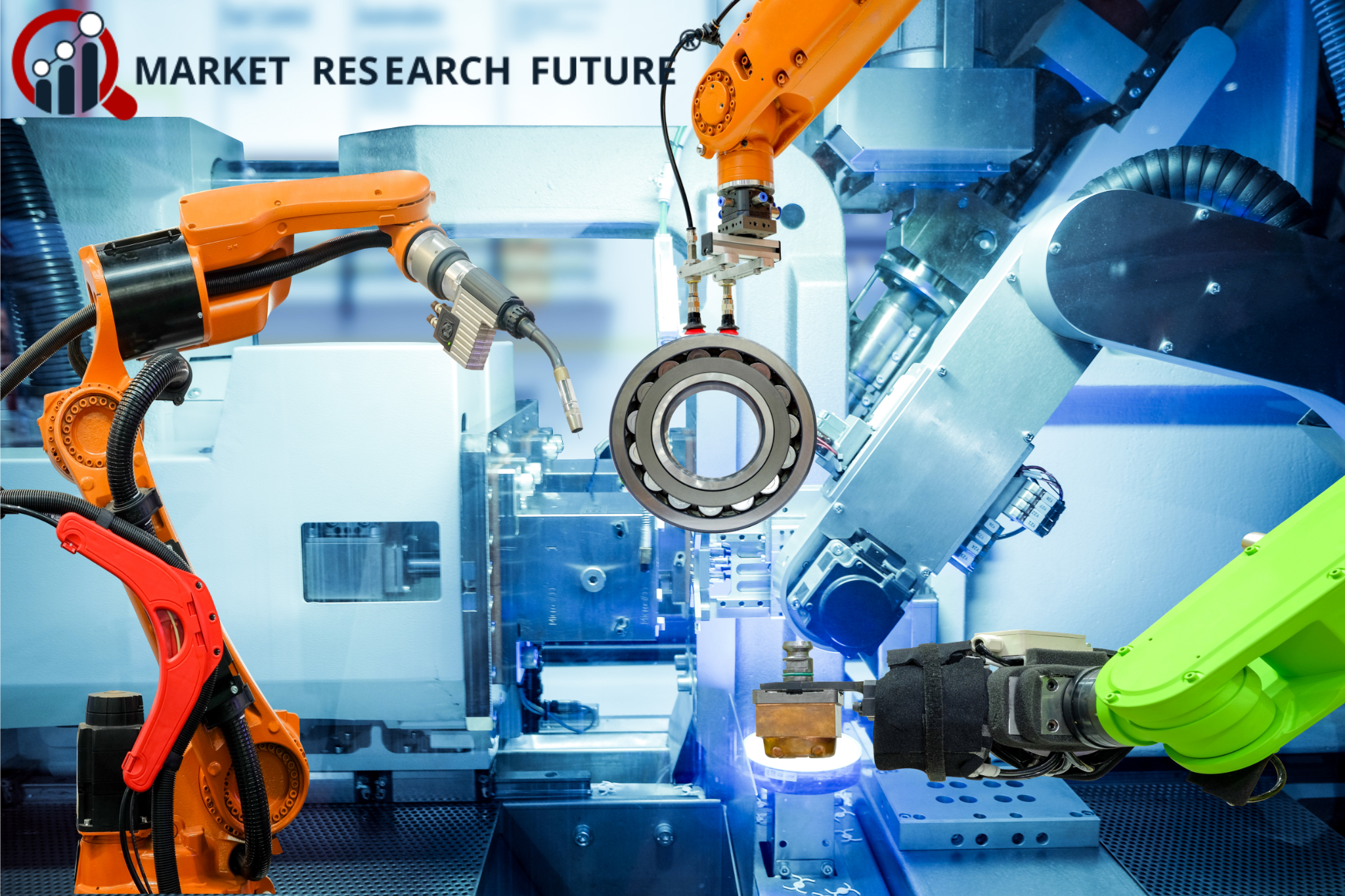

The wire rope sling market has gained significant traction in recent years due to its wide-ranging applications across industries that involve heavy lifting, rigging, and load handling. Wire rope slings are indispensable components in sectors such as construction, mining, shipping, and manufacturing. Known for their strength, flexibility, and ability to withstand harsh working conditions, these slings play a crucial role in ensuring operational efficiency and safety. With industries focusing more on robust infrastructure development and advanced lifting solutions, the demand for wire rope slings continues to rise steadily.

Importance of Wire Rope Slings in Industrial Applications

Wire rope slings are essential because they offer durability, load-bearing strength, and resistance to abrasion. Unlike other lifting alternatives, wire rope slings can adapt to varying load shapes while maintaining stability. In construction projects, they are used for lifting steel beams, concrete structures, and prefabricated materials. In the shipping industry, wire rope slings handle containers, cargo, and marine equipment. Mining companies rely heavily on them for moving ore, heavy machinery, and other raw materials. Their versatility and cost-effectiveness make them a preferred choice in industries where precision and reliability are critical.

Market Drivers Enhancing Growth

Several factors are driving the growth of the wire rope sling market. Rapid urbanization, industrialization, and the expansion of global trade are leading to higher demand for cranes, rigging equipment, and heavy load handling tools. Infrastructure projects, particularly in developing regions, require large-scale lifting solutions, which directly boosts the usage of wire rope slings. Furthermore, advancements in manufacturing technology have introduced slings with enhanced safety features, longer service life, and improved resistance to corrosion. The rise in safety regulations across industries also encourages companies to invest in certified, high-quality lifting slings.

Technological Innovations in Wire Rope Slings

The wire rope sling market has evolved significantly due to innovations in materials and design. Traditional steel wire rope slings remain dominant, but hybrid solutions with coatings and advanced alloy compositions are gaining attention. These improvements enhance tensile strength, reduce wear, and increase longevity. Additionally, manufacturers are integrating inspection technologies, such as embedded sensors, to monitor sling conditions in real time. This trend ensures predictive maintenance and minimizes the risk of accidents caused by equipment failure. By embracing innovation, the market is aligning with modern industrial demands for efficiency and safety.

Challenges in the Market

Despite the growing opportunities, the wire rope sling market faces certain challenges. One of the primary concerns is the maintenance and inspection requirements. Wire rope slings are subject to wear and tear, which necessitates regular checks to avoid accidents. Improper handling or storage can also reduce their lifespan. Another challenge comes from competition with alternative lifting solutions such as synthetic slings, which are lighter and easier to handle. However, while synthetic slings are convenient, they lack the strength and durability offered by wire rope slings in heavy-duty applications. Addressing these challenges requires awareness campaigns, skilled workforce training, and continuous innovation in product design.

Market Segmentation and Applications

The wire rope sling market can be segmented based on product type, end-use industry, and region. Common product types include single-leg, multi-leg, braided, and grommet slings, each catering to different lifting requirements. End-use industries include construction, shipping, oil and gas, mining, and general manufacturing. Among these, the construction and shipping sectors hold the largest share due to their consistent demand for lifting and rigging solutions. Regionally, Asia-Pacific stands out as a fast-growing market, driven by rapid infrastructure projects in China and India. North America and Europe also show steady growth due to their emphasis on safety standards and industrial modernization.

Competitive Landscape

The wire rope sling market is competitive, with numerous global and regional players offering specialized products. Companies focus on expanding their product portfolios, investing in research and development, and forming strategic partnerships to enhance their market presence. Many manufacturers emphasize providing customized solutions to meet industry-specific requirements. For example, slings with higher load capacity, corrosion-resistant coatings, or specialized fittings are often developed for clients in the oil and gas or marine industries. This customer-centric approach helps companies strengthen their brand reputation and gain a competitive edge.

Sustainability and Safety Considerations

Sustainability has become an important consideration in the wire rope sling market. Manufacturers are adopting eco-friendly coatings, recycling methods, and energy-efficient production techniques. Moreover, safety remains a top priority for both producers and end-users. The development of slings that comply with international safety certifications ensures confidence in their reliability. Regular training for workers on proper sling usage, inspection, and storage also contributes to minimizing workplace accidents. These practices not only safeguard human lives but also reduce operational downtime, thereby improving productivity.

Future Outlook of the Market

Looking ahead, the wire rope sling market is poised for consistent growth as industries increasingly demand safe, durable, and high-performing lifting solutions. Emerging economies with ambitious infrastructure projects will continue to drive demand. Technological integration, such as smart monitoring systems, will enhance product performance and safety. The market will also witness a rise in demand for specialized slings designed to operate in extreme conditions, including offshore oil rigs and heavy mining environments. Furthermore, the balance between traditional wire rope slings and alternative materials will shape future innovation and product development.

Conclusion

The wire rope sling market is a vital part of the global lifting and rigging equipment industry. Its importance in construction, mining, shipping, and manufacturing cannot be overstated, as these slings enable safe and efficient load handling across a wide range of applications. Despite challenges like competition from synthetic alternatives and maintenance concerns, the market continues to thrive on the back of industrial growth, technological advancements, and increasing safety regulations. With continued innovation, sustainability initiatives, and expanding applications, the wire rope sling market is set to remain a cornerstone of industrial operations worldwide.