Strong Demand Forecast Positions Polycarboxylate Ether as the Future of Concrete Admixtures

The global construction industry is undergoing a transformation, with innovation and sustainability driving material choices. Polycarboxylate ether (PCE), a high-performance superplasticizer, is at the heart of this change. It enhances concrete fluidity, reduces water consumption, and improves compressive strength — all while supporting environmentally responsible construction practices. As infrastructure investments rise globally, PCE has become integral to projects demanding durability and efficiency.

One of the major forces influencing market expansion is the growing preference for low-carbon and energy-efficient building materials. Developers and contractors are actively adopting advanced admixtures like PCE to meet green building standards and reduce the environmental footprint of concrete production. Its molecular design allows greater control over concrete flow and setting time, enabling high precision in construction processes. Moreover, the versatility of polycarboxylate ether makes it suitable for precast, ready-mix, and self-compacting concrete applications, further boosting its market reach.

The polycarboxylate ether market continues to evolve alongside global infrastructure development. Manufacturers are heavily investing in research and development to create formulations with enhanced performance under varying temperature and humidity conditions. The growing use of PCE in large-scale infrastructure, commercial, and residential projects underscores its critical role in meeting modern construction requirements.

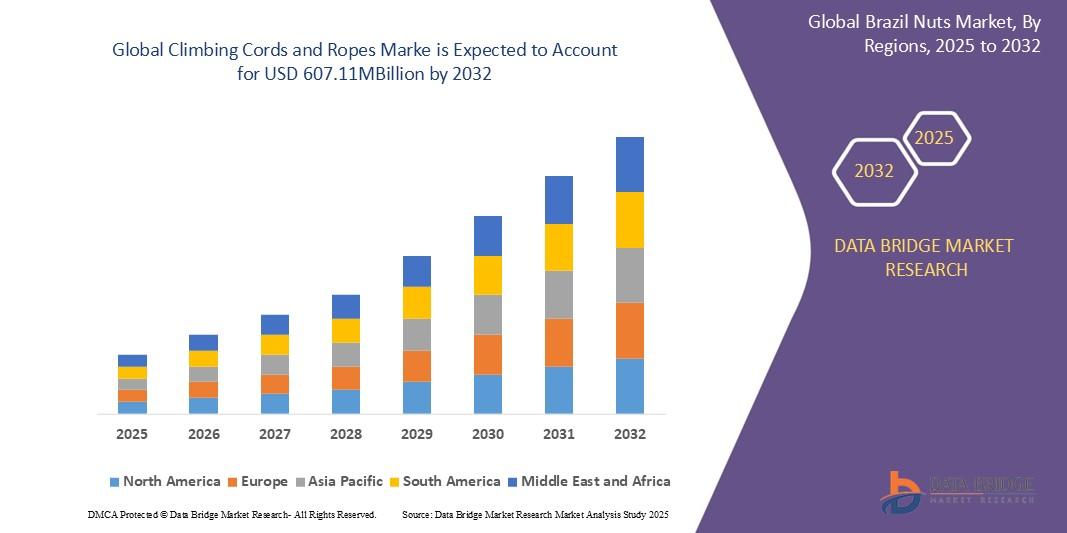

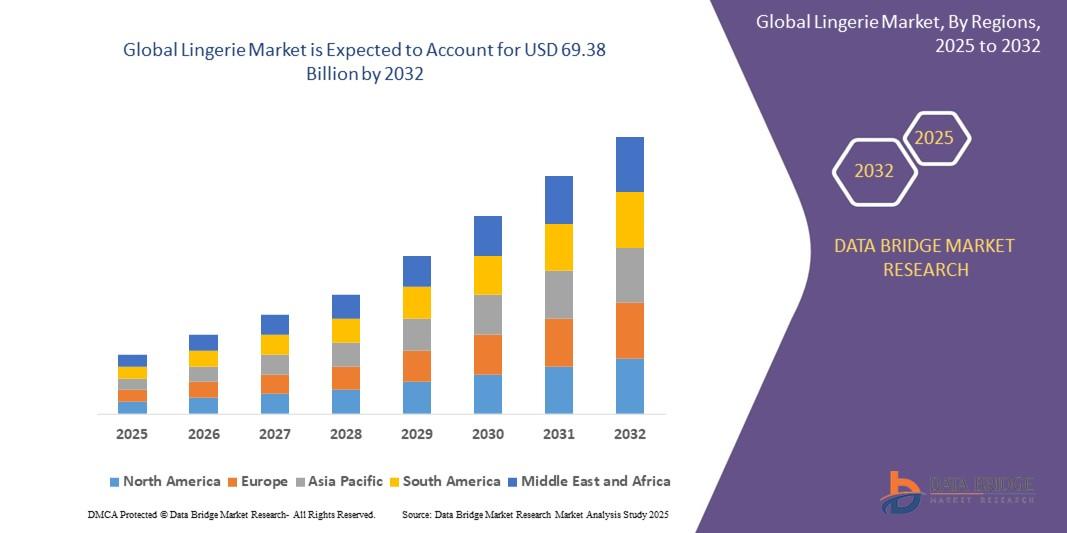

According to recent polycarboxylate ether industry trends, technological innovation and regional production expansion are shaping the next phase of growth. Asia-Pacific remains the largest market, driven by rapid urbanization and government-led infrastructure programs. In contrast, North America and Europe are focusing on sustainable construction practices and energy-efficient design standards, which further support PCE demand.

Another emerging trend is the rise of customized admixture solutions. Manufacturers are offering tailored formulations that meet specific project needs, such as enhanced slump retention, temperature tolerance, and reduced shrinkage. Additionally, the integration of digital technology in concrete design is improving mix optimization and performance tracking, leading to better quality control across projects.

As the construction industry continues to adopt smart and green solutions, PCE is poised to play a vital role in ensuring the balance between performance and sustainability. With innovation at its core, the polycarboxylate ether market is well-positioned to experience steady growth, driven by evolving industry trends, regulatory support, and technological advancements.

Browse More:

Helical Submerged Arc Welded Pipe Market Size