Impact of Automation and AI on Grinding Media Production and Performance

The grinding media market plays a pivotal role in enhancing industrial processes across sectors such as mining, cement, power generation, and metallurgy. Grinding media, which includes balls, rods, and other forms, is essential for the comminution process, where raw materials are crushed and ground into finer particles for further processing. With increasing demands for higher efficiency and reduced production costs, industries are leaning heavily on advanced grinding media to meet stringent operational requirements.

One of the major drivers fueling the grinding media market analysis is the ongoing expansion of mining operations. With the rising demand for metals and minerals such as iron ore, copper, and gold, mining companies are investing heavily in equipment that ensures higher throughput and less wear and tear. Grinding media made from high-chrome alloys and forged steel is being preferred due to its superior hardness, resistance to abrasion, and longer service life. These properties directly translate to lower maintenance costs and higher productivity.

In cement manufacturing, grinding media is crucial for crushing raw materials such as limestone and clinker. Manufacturers are now shifting towards optimized grinding processes by using tailored media shapes and sizes. This shift not only enhances the efficiency of the grinding circuits but also contributes to better particle size distribution, ultimately improving product quality.

Technological advancements are also reshaping the market. The integration of simulation software in designing grinding media and circuits allows engineers to predict wear patterns and optimize feed sizes. These innovations reduce energy consumption and improve plant reliability. Furthermore, environmental concerns have led to the development of eco-friendly grinding solutions that minimize dust emissions and energy waste.

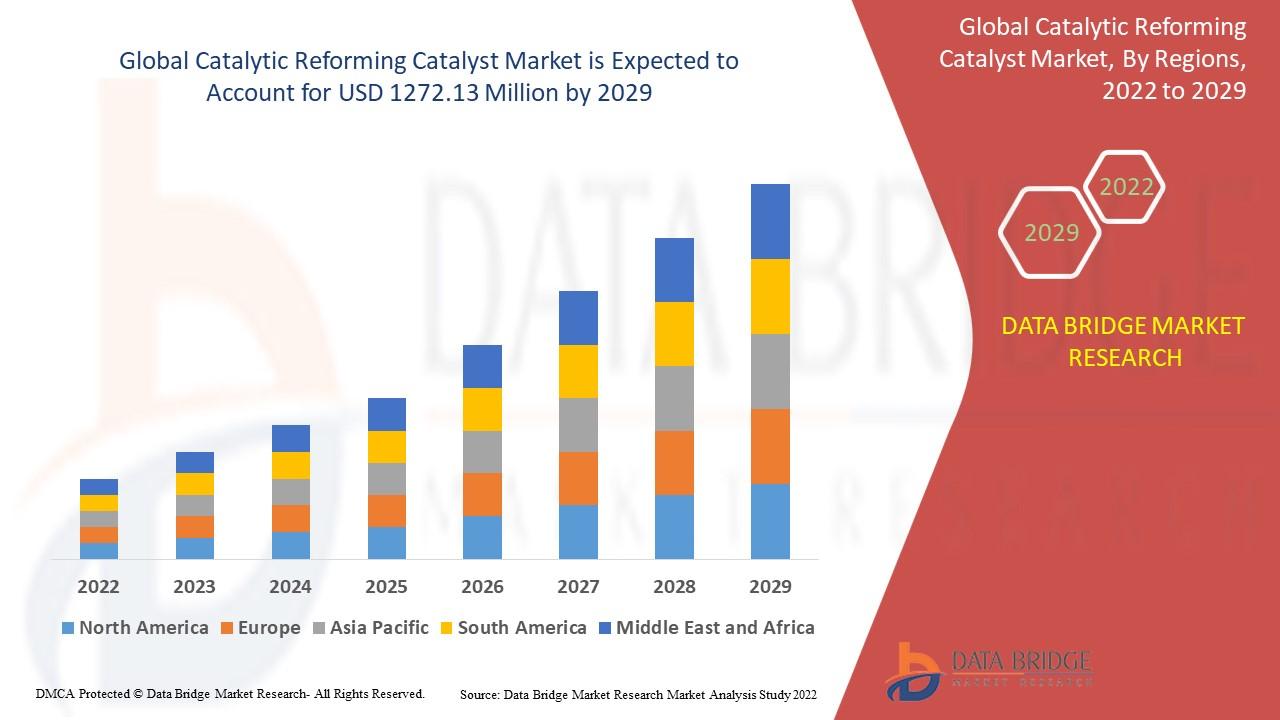

The Asia-Pacific region is expected to remain a dominant market due to rapid industrialization, particularly in countries like China and India. Growing investments in mining and infrastructure are creating an expanding demand for grinding media solutions. Meanwhile, North America and Europe are witnessing a slow but steady shift towards automation and efficiency-driven operations.

However, the market is not without challenges. The high initial cost of premium grinding media and fluctuations in raw material prices pose significant concerns for manufacturers and end-users alike. Additionally, supply chain disruptions due to geopolitical tensions and global pandemics have further strained production schedules.

Despite these challenges, the outlook remains positive as industries continue to modernize and adopt energy-efficient grinding solutions. Grinding media providers are also focusing on offering customized solutions and technical support, allowing clients to maximize operational performance.

In conclusion, the grinding media market is evolving in response to industrial demands for efficiency, durability, and sustainability. As industries across sectors prioritize cost-effective and performance-driven grinding solutions, the role of grinding media is set to grow stronger, fostering innovation and driving global industrial progress.