Liquid powder speciality coating equipment Market Growth fueled by innovation and sustainability trends

The liquid powder speciality coating equipment market growth is fueled by increasing industrialization and the need for environmentally sustainable coating processes. Advanced powder spraying systems and automated coating lines have contributed to faster production cycles and improved coating efficiency. Growth is also supported by industries seeking protective coating solutions to enhance corrosion resistance, reduce maintenance costs, and comply with stringent environmental regulations.

The liquid powder speciality coating equipment market is witnessing significant growth as industries increasingly prioritize advanced surface finishing solutions. Coating equipment is essential for providing protective and aesthetic layers to products across sectors such as automotive, aerospace, electronics, and construction. These coatings not only enhance the durability of materials but also improve corrosion resistance, weatherability, and visual appeal. The market has evolved considerably over the years, driven by technological advancements, regulatory pressures, and the growing need for high-quality coatings that meet stringent environmental and performance standards.

Market Drivers

Several factors are driving the growth of the liquid powder speciality coating equipment market. The rise in industrialization and manufacturing activities globally has resulted in a higher demand for coated products with superior surface properties. Moreover, the shift towards environmentally friendly coatings has encouraged the adoption of liquid and powder speciality coatings that reduce volatile organic compounds (VOCs) and minimize environmental impact. Industries such as automotive are investing heavily in coating technologies to produce lightweight and corrosion-resistant parts. Additionally, the demand for energy-efficient equipment and processes is fueling innovation in coating machinery, resulting in more efficient and automated systems that reduce material wastage and operational costs.

Technological Advancements

Technological innovation plays a pivotal role in shaping the liquid powder speciality coating equipment market. Modern equipment integrates advanced features such as automated spraying systems, electrostatic powder coating, and robotic application techniques. These innovations ensure uniform coating thickness, faster production cycles, and higher precision, reducing the risk of defects and enhancing overall product quality. Furthermore, developments in digital monitoring and control systems allow manufacturers to optimize the coating process, track performance, and maintain consistent quality standards. The integration of Internet of Things (IoT) and Industry 4.0 technologies is also enabling real-time monitoring, predictive maintenance, and improved process efficiency, which further strengthens the market potential for coating equipment.

Market Segmentation

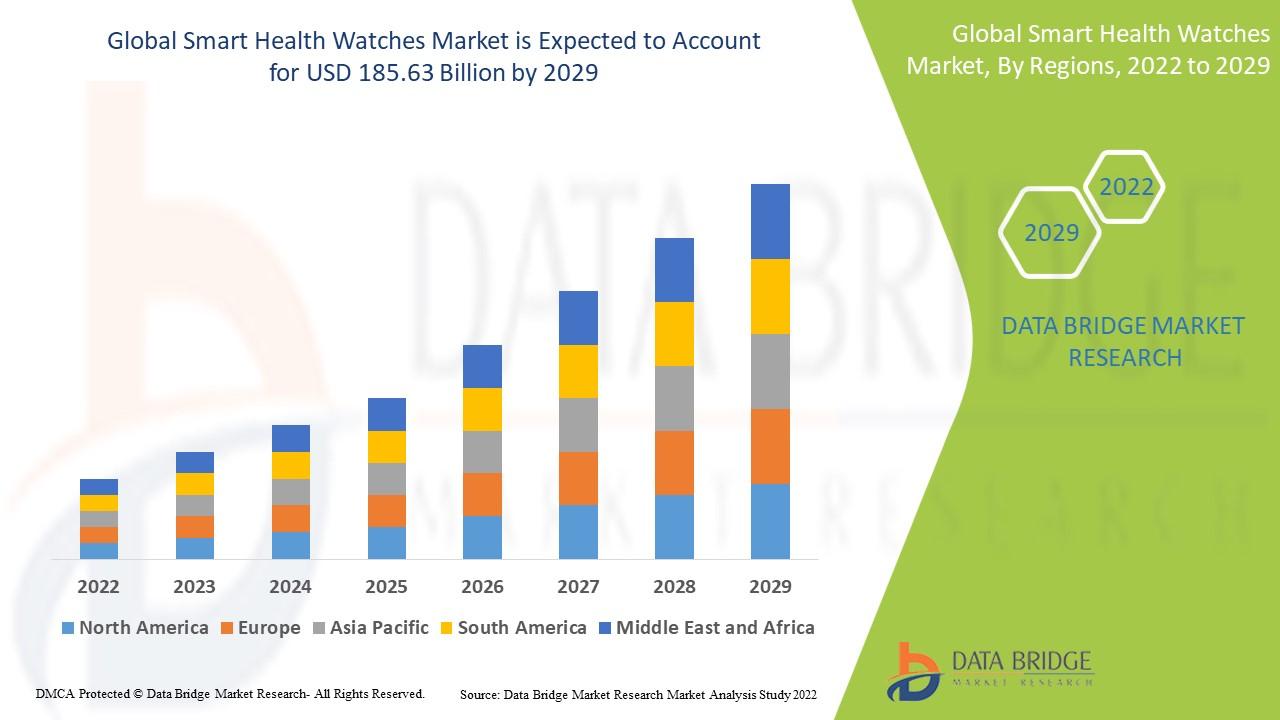

The liquid powder speciality coating equipment market can be segmented based on type, application, and end-user industry. In terms of type, equipment can be classified into liquid coating machines, powder coating machines, and hybrid systems that combine both technologies. Applications span across industries such as automotive, electronics, aerospace, construction, and furniture, each requiring specific coating methods to meet performance and aesthetic requirements. For example, the automotive sector prioritizes corrosion resistance and paint durability, while the electronics industry focuses on protective coatings for circuit boards and delicate components. Segmentation by geography indicates strong growth potential in regions such as North America, Europe, and Asia-Pacific, driven by expanding industrial activities and growing investments in manufacturing infrastructure.

Competitive Landscape

The competitive landscape of the liquid powder speciality coating equipment market is highly dynamic, with several global and regional players vying for market share. Leading manufacturers focus on product innovation, quality improvements, and strategic partnerships to maintain a competitive edge. Companies are investing in research and development to introduce cutting-edge coating technologies and equipment that meet evolving industry demands. Additionally, mergers, acquisitions, and collaborations are common strategies adopted by key players to expand their global footprint, enhance technological capabilities, and access new customer segments. The market is characterized by intense competition, with a focus on providing efficient, eco-friendly, and cost-effective solutions to meet diverse customer needs.

Market Challenges

Despite the promising growth prospects, the liquid powder speciality coating equipment market faces certain challenges. High initial investment costs for advanced coating machinery can deter small and medium-sized enterprises from adopting the latest technologies. Additionally, maintaining stringent quality standards and complying with environmental regulations require ongoing investments in process optimization and workforce training. The complexity of operating automated and robotic coating systems may also pose challenges, especially in regions with limited technical expertise. Furthermore, fluctuations in raw material prices and supply chain disruptions can impact production costs and equipment affordability, potentially affecting market growth.

Opportunities for Growth

The liquid powder speciality coating equipment market presents significant opportunities for expansion and innovation. Growing awareness of sustainable manufacturing practices and green coatings is encouraging manufacturers to adopt eco-friendly solutions. Innovations in coating materials, such as waterborne and low-VOC coatings, are driving demand for compatible equipment. Additionally, the increasing trend of customization and high-quality finishing in consumer goods offers growth potential for specialty coating systems. Emerging markets in Asia-Pacific and Latin America provide untapped opportunities, fueled by industrial growth, infrastructure development, and rising demand for advanced manufacturing technologies. Companies that invest in research, product innovation, and localized solutions are likely to capitalize on these opportunities.

Portable Filtration System Market Size