Advancements and Growth in the Automated Optical Inspection System Market Share

The global Automated Optical Inspection System Market Share is witnessing remarkable growth as manufacturers adopt advanced technologies for precision and efficiency in PCB inspection devices and semiconductor quality control. Automated Optical Inspection (AOI) systems, also known as AOI machines or vision inspection systems, are essential for detecting defects in electronic components, circuit boards, and assemblies, reducing human error, and ensuring high product reliability. The rising demand for high-quality electronics across consumer, automotive, and industrial sectors is fueling market expansion.

Key Drivers and Technological Innovations

The growth of the AOI market is driven by increased adoption of automated quality control solutions and the need for efficient defect detection. Modern industrial defect detectors integrate high-resolution cameras, AI-based algorithms, and real-time analysis tools to identify even minute faults, enhancing production efficiency and reducing waste. As electronics become more complex, AOI systems are indispensable for maintaining high manufacturing standards and compliance with industry regulations.

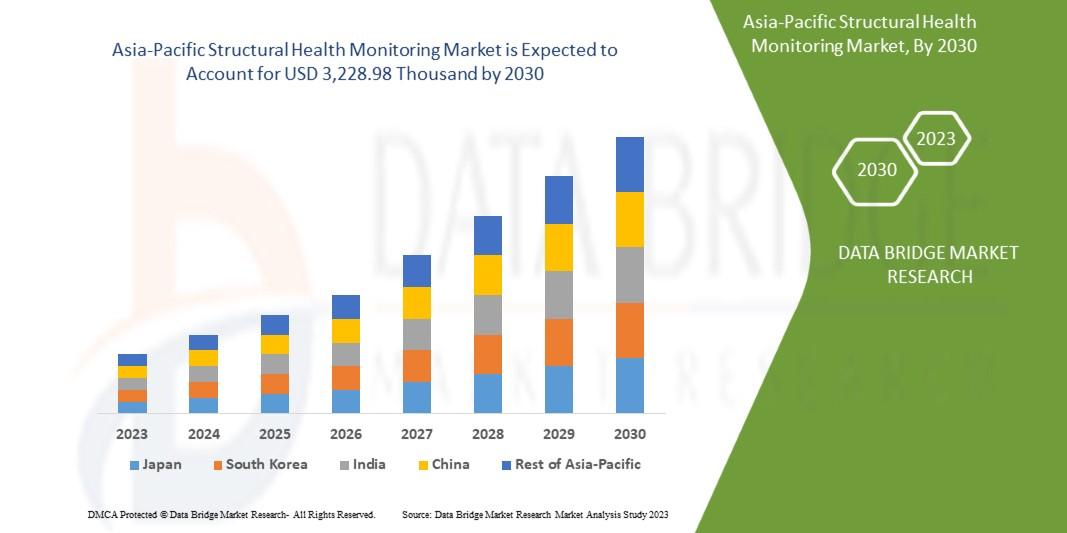

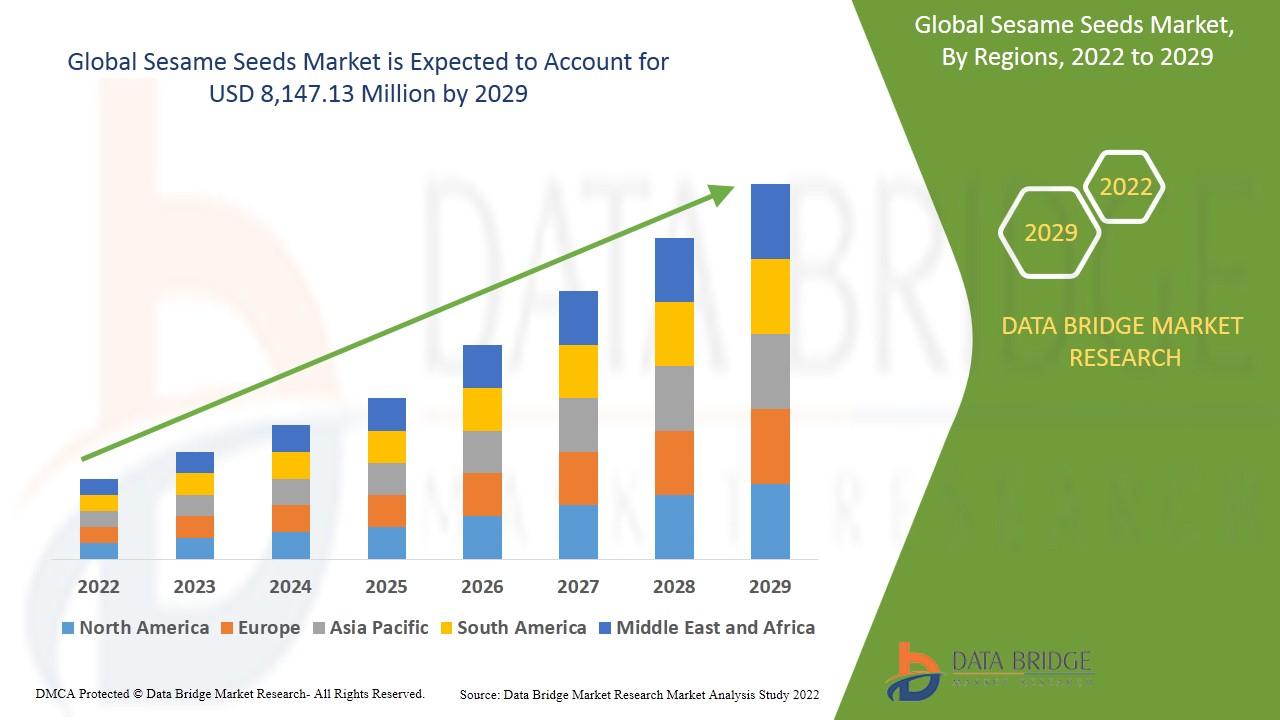

Regional Insights and Industry Trends

North America, Europe, and Asia-Pacific lead the AOI market due to technological advancements, growing electronics manufacturing, and rising investments in automated production lines. For instance, related markets such as the Germany Field Programmable Gate Array Market and France Serdes Market demonstrate parallel growth trends in semiconductor technology, reflecting the increasing reliance on high-precision manufacturing and inspection systems.

Future Outlook of AOI Systems

The future of the Automated Optical Inspection System Market looks promising as manufacturers continue to prioritize defect-free production and operational efficiency. Advancements in AI-powered inspection, multi-angle imaging, and high-speed processing are expected to drive adoption across electronics, automotive, aerospace, and medical device sectors. With increasing investments in automated manufacturing technologies, AOI machines and vision inspection systems will play a critical role in ensuring high-quality standards and reducing production costs.

FAQs

1. What are the main applications of AOI systems?

AOI systems are primarily used in PCB inspection devices, semiconductor manufacturing, automotive electronics, and other high-precision industrial production lines for defect detection and quality control.

2. How do automated optical inspection systems improve manufacturing efficiency?

By leveraging industrial defect detectors and AI-driven vision systems, AOI machines reduce human error, accelerate inspection speed, and ensure consistent product quality, ultimately minimizing waste.

3. Which regions are leading in AOI system adoption?

North America, Europe, and Asia-Pacific are leading due to advanced electronics manufacturing infrastructure, rising automation adoption, and increasing demand for high-quality electronic components.