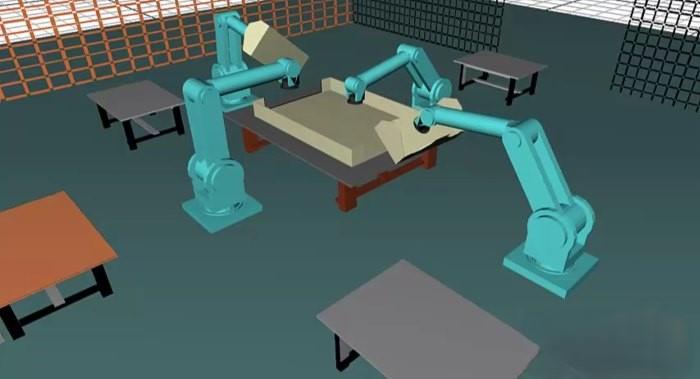

CNC Cutting Technology Advancing Smart Manufacturing and Custom Metal Processing

CNC cutting technology is revolutionizing the cutting equipment market by offering precision and automation in manufacturing processes. CNC (Computer Numerical Control) systems enable manufacturers to achieve high levels of accuracy and repeatability in cutting operations. The growing demand for complex and intricate designs in various industries, including aerospace and automotive, is driving the adoption of CNC cutting technology. As companies seek to enhance productivity and reduce labor costs, CNC cutting solutions are becoming increasingly popular in the market.

The Cutting Equipment Market has evolved into a crucial part of the global manufacturing and metalworking industries. From automotive and aerospace to construction and energy, cutting technologies are essential for shaping materials with accuracy and efficiency. With the advent of automation and smart manufacturing, modern cutting equipment is redefining productivity standards. The demand for advanced cutting systems continues to rise as industries seek improved precision, lower production costs, and enhanced sustainability.

Market Overview

Cutting equipment includes various machines such as plasma cutters, laser cutters, waterjet cutters, and oxy-fuel systems. These machines are widely used in industries that require metal fabrication and complex design cutting. The market has witnessed strong growth due to the expanding manufacturing sector and increasing use of high-performance materials. Manufacturers are focusing on automation and digitalization to meet the growing demand for precision and productivity. The global trend toward Industry 4.0 has further accelerated the integration of smart cutting technologies.

Technological Advancements

Innovation plays a vital role in the cutting equipment market. The development of fiber laser cutting machines, automated CNC-controlled cutting systems, and IoT-enabled monitoring tools has significantly improved cutting accuracy and operational efficiency. Energy-efficient and high-speed cutting tools are reducing material waste while boosting throughput. Furthermore, hybrid machines capable of handling multiple materials are gaining traction, especially in aerospace and automotive applications where diverse materials are used.

Market Drivers

The key drivers fueling market growth include rising industrial automation, expansion of the construction sector, and the adoption of lightweight materials in automotive and aerospace industries. Increased demand for customized metal fabrication, coupled with advancements in additive and subtractive manufacturing, is also pushing market development. Additionally, the global push for clean and efficient energy solutions, such as wind and solar power, has amplified the need for precise cutting equipment in turbine and panel production.

Market Challenges

Despite the growing opportunities, the cutting equipment market faces challenges such as high initial investment, maintenance costs, and the need for skilled labor. The rapid technological evolution requires continuous training and adaptation. Environmental regulations concerning metal cutting emissions and the disposal of waste materials also pose operational constraints. However, ongoing research and development in eco-friendly and automated solutions are expected to mitigate these challenges.

Regional Insights

The Asia-Pacific region dominates the global cutting equipment market due to rapid industrialization, infrastructure development, and strong manufacturing bases in China, India, and Japan. North America and Europe follow, driven by technological advancements and the adoption of automated manufacturing systems. Meanwhile, the Middle East and Africa are emerging as potential markets with rising construction and industrial projects.

Future Outlook

The future of the cutting equipment market is centered on digital transformation, sustainability, and innovation. The integration of robotics, AI, and machine learning in cutting operations will revolutionize industrial manufacturing. Additionally, the focus on green manufacturing practices will encourage the development of energy-efficient and low-emission cutting technologies.

Conclusion

The Cutting Equipment Market continues to expand as industries prioritize precision, automation, and efficiency. The rising demand for advanced fabrication solutions, coupled with technological innovations, ensures sustained growth in the years ahead.

Get Free Sample PDF Brochure:

Buy Now Premium Research Report:

Browse In-depth Market Research Report: Regional Insights

FAQs

Q1: Which type of cutting technology is most in demand?

Laser cutting and plasma cutting technologies are witnessing the highest demand due to their precision and speed.

Q2: What industries use cutting equipment the most?

Major users include automotive, construction, aerospace, shipbuilding, and metal fabrication sectors.

Q3: What trends are shaping the cutting equipment market?

Automation, digital integration, and the rise of smart manufacturing are key trends shaping the market.

More Related Reports:

End Load Cartoning Machine Market Share

Brake Lathe Machine Market Share