Computer-controlled grinding systems Boosting Efficiency in High-Precision Production

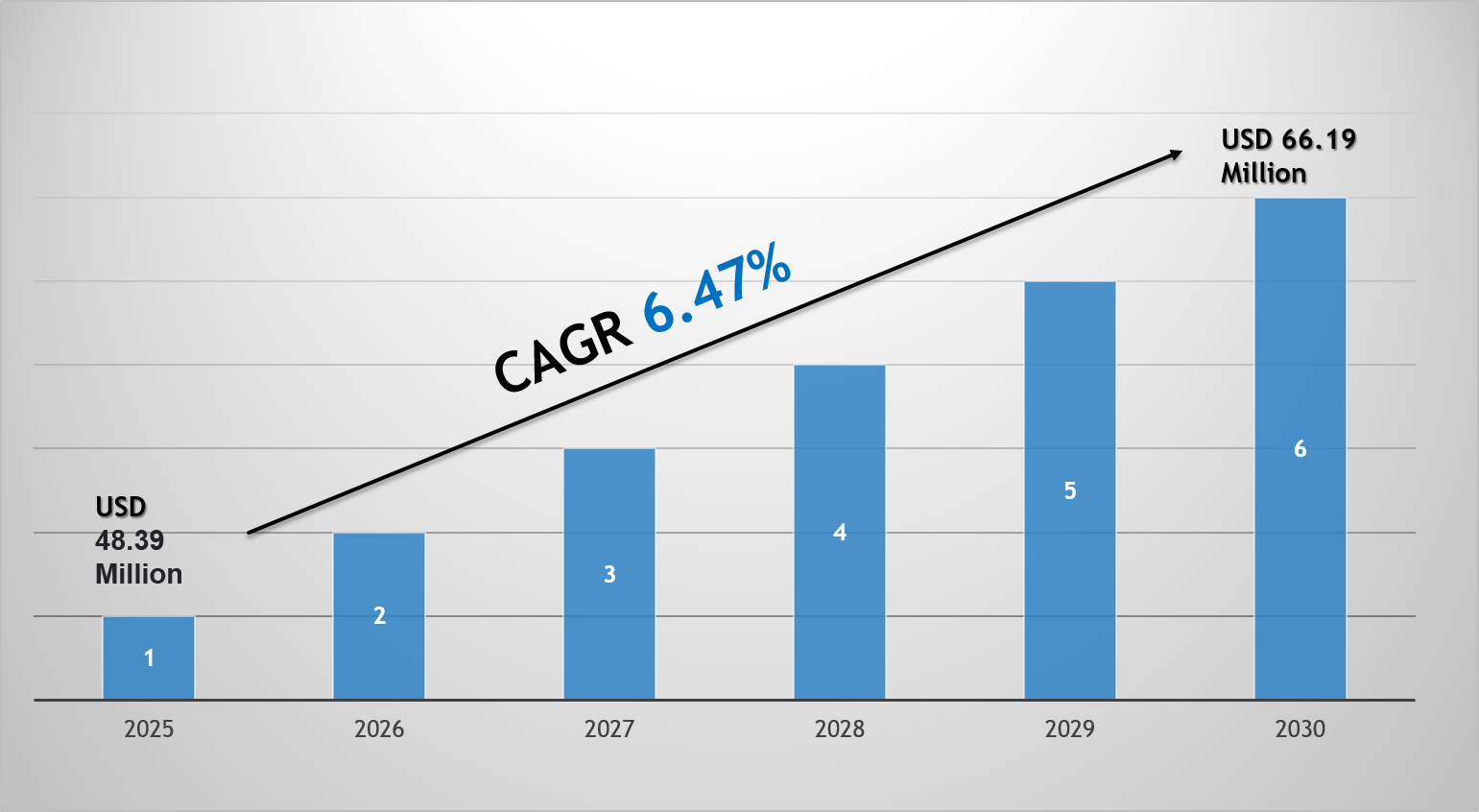

Computer-controlled grinding systems are at the forefront of modern manufacturing, providing enhanced precision and efficiency in tool production. These systems utilize advanced CNC technology to automate the grinding process, reducing human error and increasing output quality. The growing trend towards automation in manufacturing is driving the adoption of these systems, as companies seek to optimize their operations and improve product quality. As a result, the market for computer-controlled grinding systems is expected to witness significant growth in the coming years.

The CNC tool and cutter grinding machine market has emerged as a key segment within the precision machinery industry, driven by the demand for high-accuracy machining and advanced manufacturing techniques. These machines are designed to sharpen, grind, and produce cutting tools with superior precision, which is vital for applications in automotive, aerospace, and defense industries. As the manufacturing landscape evolves toward automation and digital control, CNC grinding machines have become integral to ensuring consistent tool quality and production efficiency.

Market Dynamics and Growth Factors

The growth of the CNC tool and cutter grinding machine market is fueled by the increasing complexity of modern tools and the rising need for automated grinding solutions. Traditional manual grinding methods are being replaced by CNC systems that provide higher accuracy, repeatability, and reduced operational errors. Additionally, the growing use of hard-to-machine materials such as titanium and composites in aerospace and automotive manufacturing has increased the demand for advanced CNC grinding machines capable of handling complex geometries. Furthermore, industries are focusing on reducing downtime and improving tool life, which has encouraged the adoption of smart grinding machines with predictive maintenance features.

Technological Innovations and Advancements

Recent technological developments have revolutionized CNC grinding machines. Integration of artificial intelligence, robotics, and cloud connectivity has made these systems smarter and more efficient. Machines now come with automatic wheel changers, adaptive control systems, and real-time process monitoring to enhance production accuracy. Software advancements allow for precise tool simulation and optimization before actual grinding begins, minimizing waste and setup time. In addition, 5-axis CNC machines are gaining popularity as they enable multi-surface grinding and complex tool shapes in a single setup, significantly boosting productivity.

Applications and Regional Trends

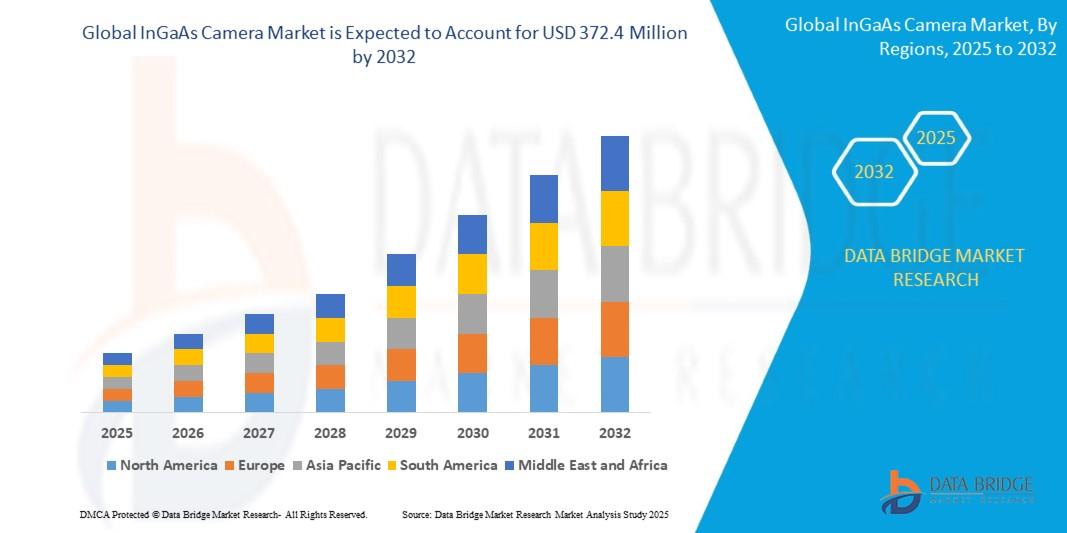

CNC tool and cutter grinding machines find extensive applications across industries that require precision tooling—such as automotive, aerospace, power generation, and medical devices. Asia-Pacific dominates the market due to the strong presence of manufacturing hubs in China, Japan, and India. Europe follows closely, driven by advanced engineering sectors and strong R&D investments. North America also presents considerable growth opportunities due to the increasing focus on reindustrialization and digital manufacturing technologies.

Market Challenges and Future Opportunities

Despite the rising demand, the market faces challenges such as high machine costs, complex maintenance needs, and the shortage of skilled operators. However, with ongoing digitalization and the growing adoption of Industry 4.0 standards, these issues are gradually being mitigated. The future of the CNC tool and cutter grinding machine market lies in automation, real-time data analytics, and energy-efficient operations. As companies focus on achieving higher precision and productivity, the market is expected to witness consistent growth over the next decade.

FAQs

Q1: What is a CNC tool and cutter grinding machine used for?

It is used to sharpen, grind, and produce precision cutting tools for manufacturing industries.

Q2: Which industries use CNC grinding machines the most?

Major users include the automotive, aerospace, and metalworking industries.

Q3: What are the major trends shaping the market?

Automation, AI integration, and multi-axis grinding technologies are key trends.

More Related Reports: