The Digital Twin: An Introduction to 3D Simulation Software

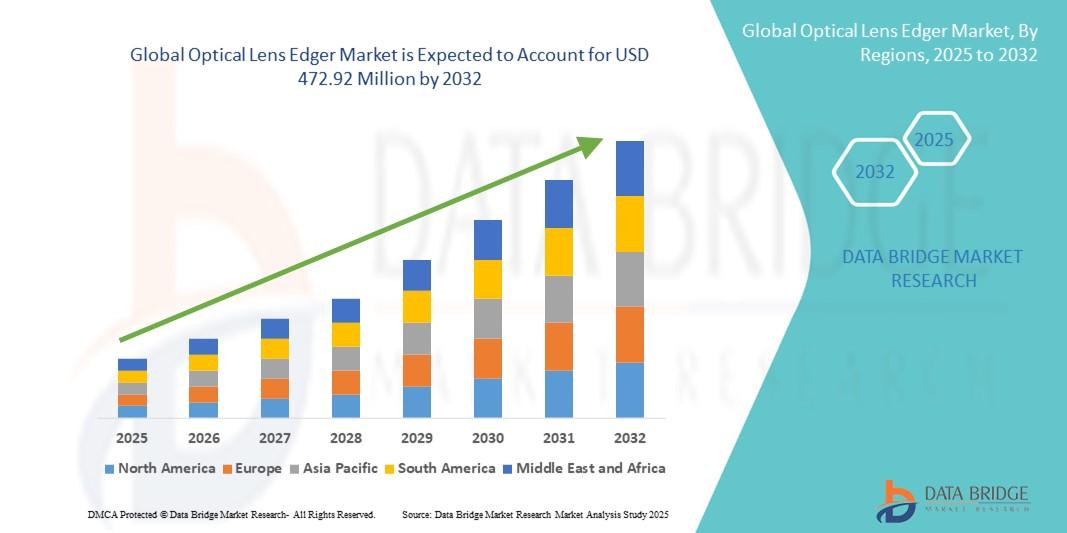

In the world of modern engineering, design, and scientific research, the ability to test, validate, and optimize in a virtual world before committing to the physical one is a game-changing capability. This is the power of 3D Simulation Software, a sophisticated category of computer-aided engineering (CAE) that allows users to create a dynamic, physics-based digital model of a product, process, or system. This "digital twin" can then be subjected to a wide range of virtual tests to predict its real-world behavior, from the structural stress on an aircraft wing to the airflow over a new car design. The immense value this provides in accelerating innovation and reducing costs is driving massive market growth, with the industry projected to grow to a valuation of $39.64 billion by 2035, powered by a phenomenal compound annual growth rate of 17.02% during the 2025-2035 forecast period.

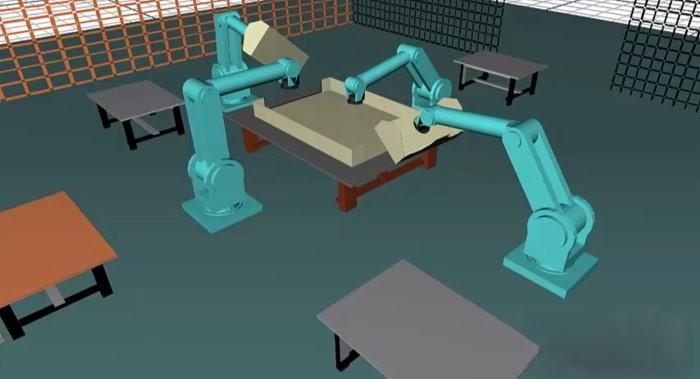

At its core, 3D simulation software uses complex mathematical models and algorithms to replicate the laws of physics in a virtual environment. The process typically begins with a 3D computer-aided design (CAD) model of a product or system. This geometric model is then imported into the simulation software and is broken down into a "mesh" of millions of small elements. The user then applies a set of boundary conditions, such as forces, pressures, temperatures, and material properties. The software's "solver" then performs an enormous number of calculations to predict how the model will behave under those conditions. The results are then presented to the engineer or scientist as a detailed visual animation, showing stress concentrations, fluid flow patterns, or thermal gradients, providing invaluable insights.

The applications for 3D simulation are incredibly diverse and span almost every major industry. In the automotive and aerospace sectors, it is an indispensable tool. Engineers use it for virtual crash testing, computational fluid dynamics (CFD) to optimize aerodynamics, and structural analysis to make vehicles lighter and stronger. In the electronics industry, it is used to simulate heat dissipation in complex microchips and to model the electromagnetic performance of antennas. In healthcare, it is used to simulate blood flow through an artery to design better stents or to model the biomechanics of a prosthetic limb. In architecture and construction, it is used to simulate wind loads on a skyscraper or the evacuation of a building in an emergency.

Ultimately, the primary benefit of 3D simulation software is its ability to dramatically reduce the reliance on expensive and time-consuming physical prototyping and testing. Instead of building dozens of physical car prototypes to crash test, an automaker can run thousands of virtual crash simulations in a fraction of the time and cost. This "front-loading" of the design process allows engineers to explore a much wider range of design alternatives, identify potential problems early, and arrive at a more optimized and robust final product. This acceleration of the innovation cycle, combined with significant cost savings and the ability to create superior products, is the fundamental value proposition that is driving the rapid and widespread adoption of this transformative technology.

Explore Our Latest Trending Reports:

Business Management Consulting Service Market