Transformer Oil Diagnostics: Ensuring Reliable Power System Performance

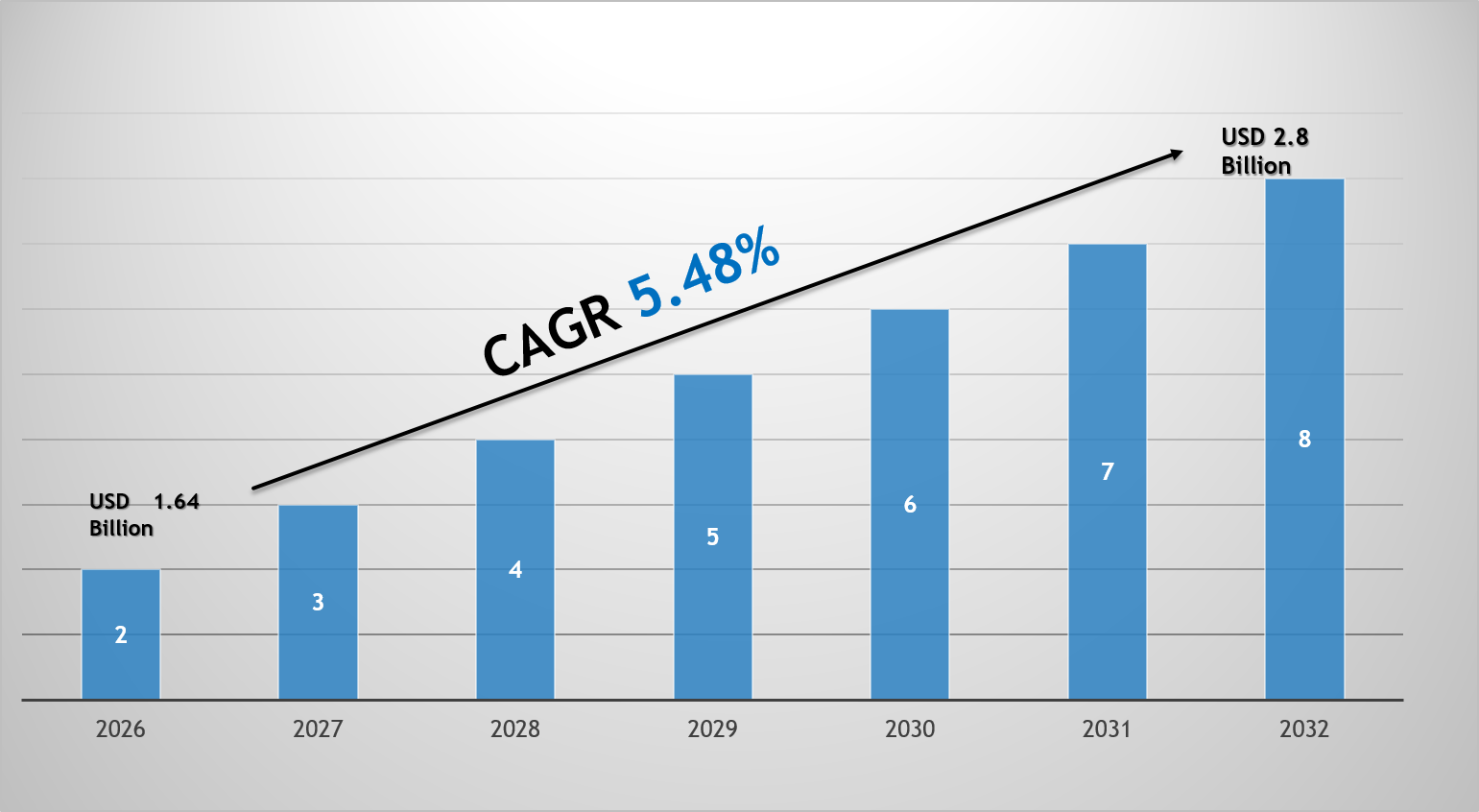

As per Market Research Future, the global demand for advanced dissolved gas analyzers is rising steadily, driven by the need for enhanced transformer oil diagnostics and maintenance practices. Transformer oil is a critical component in power systems, serving not only as an insulator but also as a coolant for transformers. Over time, the oil undergoes degradation due to thermal stress, electrical discharges, and contamination, making regular diagnostics essential to prevent failures and extend the lifespan of transformers.

Transformer oil diagnostics involves a series of tests and monitoring techniques designed to evaluate the quality and performance of the insulating oil. These diagnostics are crucial because transformer failures can lead to significant operational disruptions and costly repairs. The most common issues that transformer oil diagnostics help detect include moisture content, dissolved gases, acidity, and particulate contamination. By identifying potential problems early, maintenance teams can implement corrective measures, thereby improving the reliability and safety of the power distribution system.

One of the key diagnostic techniques is Dissolved Gas Analysis (DGA). DGA helps identify the presence of gases such as hydrogen, methane, ethylene, and acetylene, which are produced due to different types of faults within the transformer. Each gas type and its concentration provide valuable insights into the transformer’s health, allowing engineers to predict issues like overheating, arcing, or insulation breakdown. Modern DGA instruments are highly sensitive and capable of detecting minute concentrations of gases, ensuring precise and timely monitoring.

Another essential diagnostic method is the Breakdown Voltage Test, which measures the electrical strength of transformer oil. A decrease in breakdown voltage indicates contamination or moisture ingress, both of which compromise the insulating properties of the oil. Regular monitoring helps in taking preventive actions such as oil filtration, dehydration, or replacement, ensuring the transformer continues to operate efficiently.

Moisture analysis is equally important, as water dissolved in transformer oil significantly reduces its dielectric strength. Techniques like the Karl Fischer titration method provide accurate measurements of water content in oil. High moisture levels often signal leaks or failures in the transformer’s sealing systems, prompting immediate maintenance intervention.

Furan analysis is another diagnostic tool widely used to assess the condition of cellulose-based insulation in transformers. Furans are by-products of paper degradation, and their presence in oil indicates aging or deterioration of insulation. By tracking furan levels, maintenance teams can estimate the remaining lifespan of the transformer and plan timely replacements or repairs.

The integration of online monitoring systems has transformed transformer oil diagnostics by providing real-time data on key parameters such as temperature, moisture, and dissolved gases. These systems enhance predictive maintenance strategies, allowing utilities to avoid unplanned outages and extend asset life. Furthermore, the combination of online monitoring with laboratory-based diagnostics creates a comprehensive approach to transformer health assessment.

In addition to protecting equipment, transformer oil diagnostics contribute to operational efficiency and safety. By reducing the likelihood of transformer failures, utilities can avoid costly downtime, maintain stable power delivery, and minimize environmental hazards associated with oil leaks or explosions. Companies investing in advanced diagnostic tools not only enhance reliability but also comply with regulatory standards and improve asset management practices.

With increasing power demand and aging transformer infrastructure, the role of transformer oil diagnostics has become more critical than ever. Adopting advanced diagnostic techniques ensures that transformers operate at optimal performance, reduces maintenance costs, and supports the sustainable growth of the power industry.

FAQs

Q1: How often should transformer oil diagnostics be performed?

A1: The frequency depends on transformer age, load conditions, and environmental factors. Typically, comprehensive diagnostics are conducted annually, while online monitoring provides continuous assessment.

Q2: What are the most common faults detected by dissolved gas analysis?

A2: DGA can detect overheating, arcing, partial discharges, and insulation degradation, allowing maintenance teams to prevent serious transformer failures.

Q3: Can transformer oil be restored instead of replaced?

A3: Yes, depending on the level of contamination or degradation, techniques like filtration, dehydration, and degassing can restore oil properties, extending its usable life.

More Related Reports:

Fuel Cell Gas Diffusion Layer Market