Aerospace and Automotive Industries Fueling Polyamide Imide Resin Market Expansion

The growing complexity of engineering design across aerospace and automotive industries has led to an increasing preference for materials that offer both performance and endurance. Polyamide-imide (PAI) resin has positioned itself as a vital component in advanced manufacturing processes due to its high heat tolerance, exceptional mechanical strength, and resistance to wear and corrosion. These attributes make it a go-to material for components such as bearings, gaskets, and high-temperature electrical insulators.

In the automotive industry, the global transition to electric and hybrid vehicles has intensified the need for high-performance materials that can withstand thermal stress while maintaining lightweight characteristics. Similarly, the aerospace sector depends on materials like PAI resins for critical parts exposed to extreme operational conditions. These include engine components, structural supports, and wire coatings where reliability is paramount.

The Polyamide Imide Resin Market continues to benefit from innovations in composite manufacturing, as engineers strive to improve efficiency and fuel economy through better material design. Emerging trends also highlight the growing integration of PAI with carbon fibers to enhance stiffness and thermal performance.

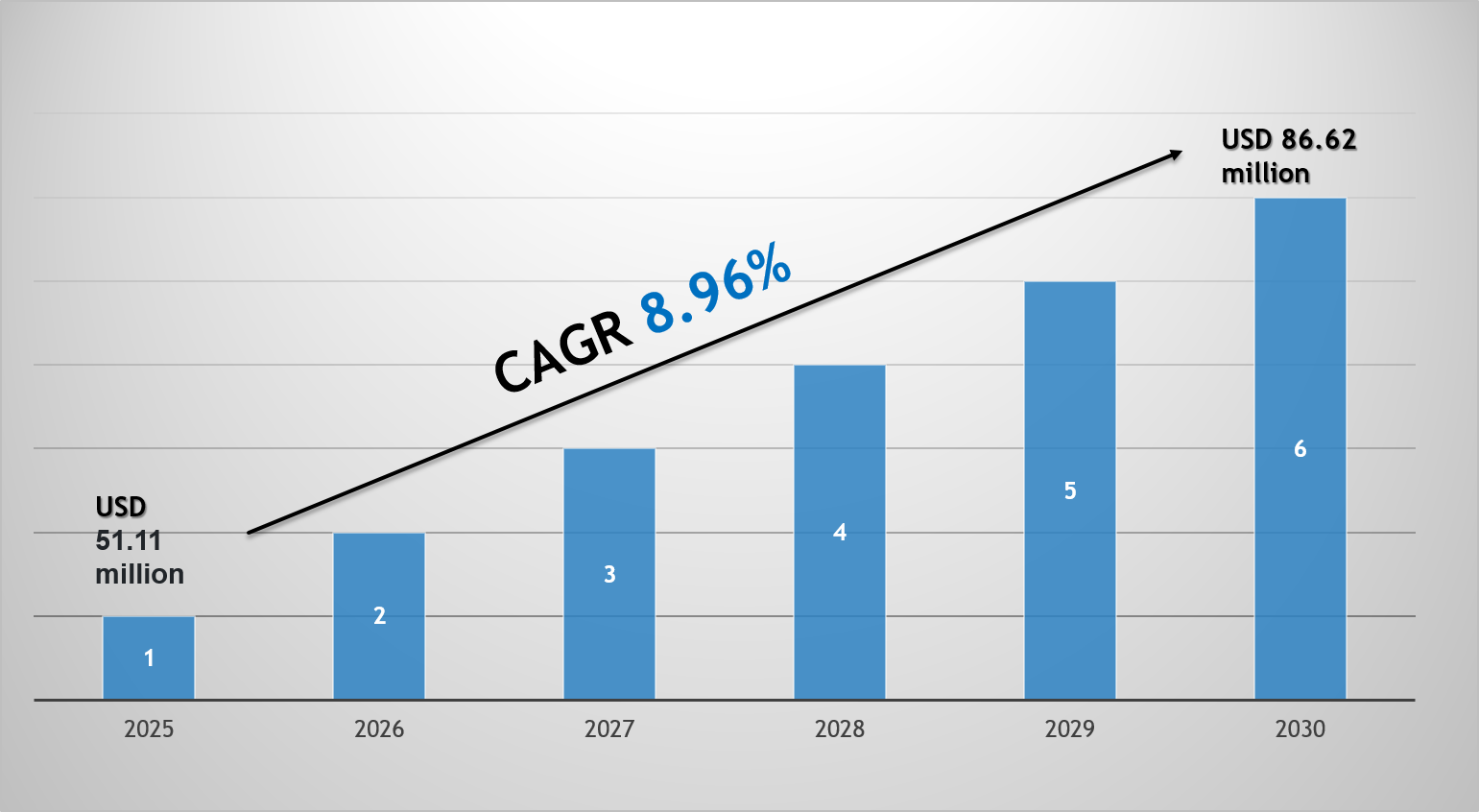

Through a detailed Polyamide Imide Resin market segmentation, analysts observe that demand is particularly strong in Asia-Pacific and North America, where automotive production and aerospace development remain robust. With the global shift toward high-performance polymers, the use of PAI resins is projected to expand significantly across mobility and industrial applications in the next decade.